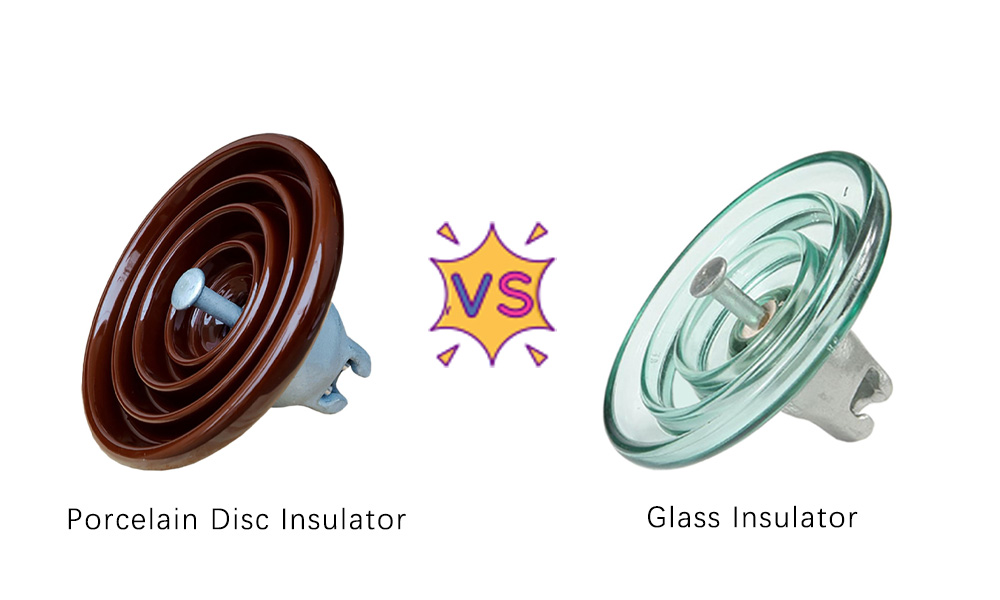

Les isolateurs en porcelaine disque et les isolateurs en verre sont largement utilisés dans les systèmes de transmission et de distribution d'électricité à haute tension. Leur fonction principale est de supporter mécaniquement les conducteurs tout en assurant une isolation électrique par rapport aux pylônes de transmission. Bien que les deux réalisent efficacement cette tâche, leurs performances présentent des différences significatives.

Les principales différences entre les isolateurs en porcelaine disque et les isolateurs en verre disque en termes de matériaux, de performances et d'applications sont les suivantes :

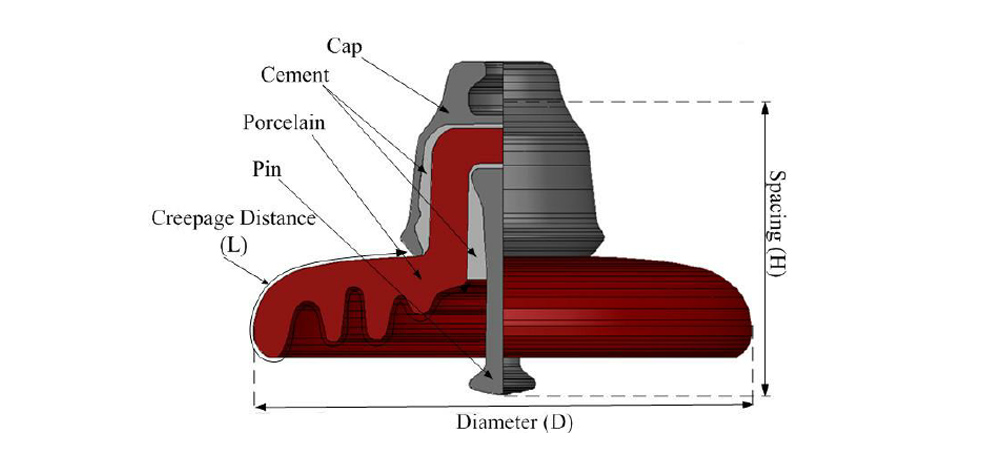

Matériaux d'isolateur différents

- Isolateurs en porcelaine disque: Fabriqués en porcelaine électrique à haute résistance (généralement porcelaine à l'alumine) avec une surface glaçurée pour améliorer l'isolation et la résistance à la pollution.

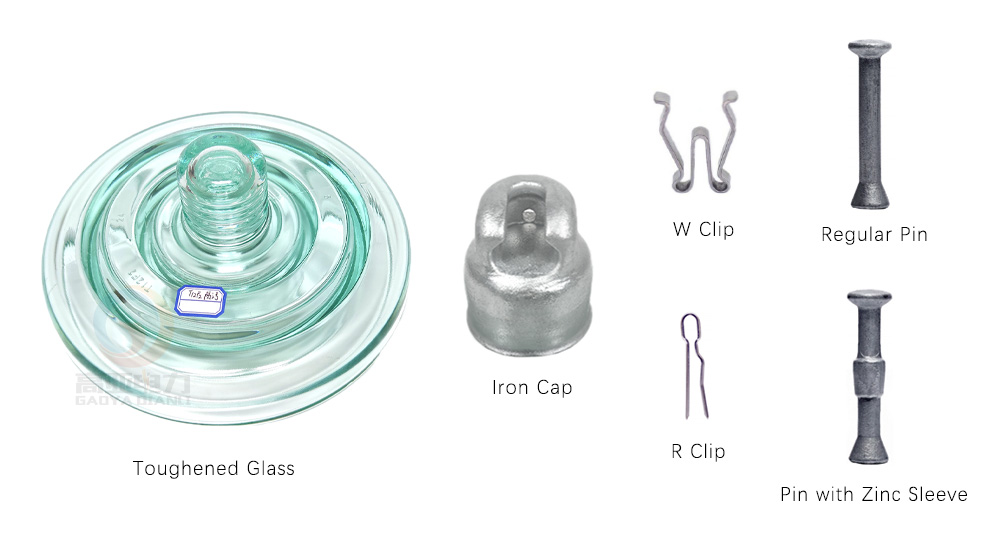

- Isolateurs en verre: Fabriqués en verre trempé, qui subit un processus de trempe pendant la fabrication pour atteindre une résistance mécanique plus élevée.

Propriétés mécaniques et électriques

| Performance | Isolateur en porcelaine disque | Isolateurs en verre |

| Résistance mécanique | Haute résistance, bonne résistance à la traction, mais susceptible de se fendre | Facile à casser par impact externe, mais le verre trempé présente une résistance plus élevée |

| Résistance aux impacts | Susceptible de développer des microfissures et de vieillir avec le temps | Surface du verre lisse et résistance aux impacts forte |

| Performance d'isolation | Affectée par l'humidité et la pollution | Matériau verrier avec une isolation plus stable |

| Résistance au vieillissement | La performance peut diminuer avec l'utilisation prolongée due à des changements de température ou à la corrosion environnementale | Le verre présente une fonction de détection du vieillissement automatique (une rupture se traduit par une fragmentation) |

Exploitation et maintenance

Isolateurs en porcelaine disque :

- Susceptibles de développer des fissures cachées, difficiles à détecter et nécessitant des inspections régulières.

- Fortement affectés par les conditions environnementales et susceptibles de vieillir dans des environnements humides ou pollués.

Isolateurs en verre :

- Propriété auto-destructrice : Si la structure interne est endommagée, l'isolateur en verre se brise automatiquement, empêchant les unités défectueuses de rester en service. Cela facilite l'identification et le remplacement des isolateurs défectueux.

- Moins affectés par les facteurs environnementaux, avec une longue durée de vie. Même après 30 à 40 ans d'exploitation, les isolateurs en verre conservent leur résistance mécanique et leurs performances électriques, garantissant la fiabilité et réduisant les coûts de remplacement.

Environnements d'application

- Isolateurs en porcelaine disque : Adaptés à diverses conditions climatiques, mais peuvent nécessiter des mesures anti-pollution supplémentaires dans des environnements fortement pollués ou humides.

- Isolateurs en verre : Grâce à leur surface lisse, ils résistent à l'accumulation de saletés et sont idéaux pour les zones fortement polluées et à haute humidité, telles que les régions côtières et industrielles.

Considerations économiques

- Les isolateurs en verre sont généralement plus économiques en raison de leur processus de fabrication mature et de coûts de matière relativement plus bas.

- Les isolateurs en porcelaine disque peuvent présenter des coûts globaux plus élevés en raison de leur processus de fabrication complexe et de la nécessité d'une maintenance plus fréquente.