Un isolateur verre ligne haute tension, également appelé isolateur en verre trempé, est un composant d’isolation utilisé sur les lignes de transport et de distribution d’électricité à haute tension. Il est généralement assemblé en chaînes pour soutenir les conducteurs et empêcher toute fuite de courant. Introduit dans les années 1950, l’isolateur verre ligne haute tension est largement utilisé en raison de sa grande résistance mécanique et de ses excellentes performances électriques.

Comment sont fabriqués les isolateurs verre ligne haute tension ?

Un isolateur verre ligne haute tension est composé d’un disque en verre trempé, d’un chapeau et d’une tige en acier galvanisé à chaud, ainsi que d’un clip de sécurité en acier inoxydable, le tout collé à l’aide d’un ciment à haute résistance.

Processus de fabrication du disque en verre trempé :

1. Préparation des matières premières - 2. Fusion - 3. Moulage - 4. Recuisson - 5. Trempe (ou durcissement thermique) - 6. Contrôle qualité - 7. Stockage et transport

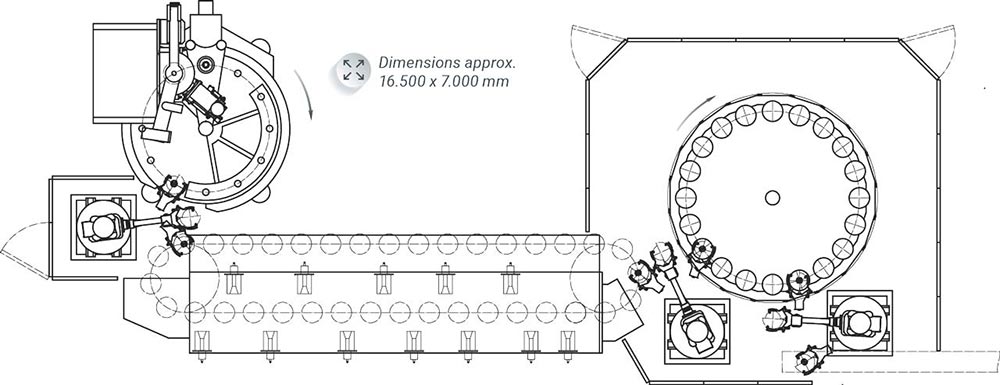

Diagramme de ligne de production pour isolateurs en verre à haute tension

Comment fonctionne un isolateur verre ligne haute tension ?

Soutien mécanique

Les isolateurs verre ligne haute tension résistent aux contraintes mécaniques telles que la traction, le vent et les charges de glace grâce à :

- La résistance du verre trempé – augmente la durabilité et assure la stabilité de la ligne.

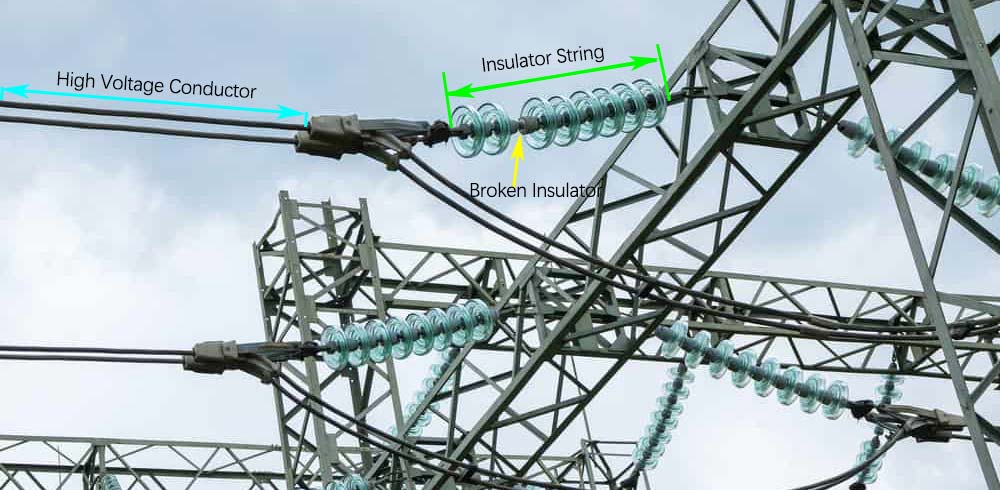

- La configuration en série – plusieurs isolateurs en chaîne s’adaptent aux différentes tensions et charges.

- La fonction d’auto-destruction – en cas de rupture, le verre se fragmente en toute sécurité tandis que les pièces métalliques restent connectées, évitant ainsi une défaillance du système.

Isolation électrique

Les isolateurs verre ligne haute tension empêchent les conducteurs haute tension de fuir du courant vers les pylônes ou poteaux mis à la terre grâce à :

- Un matériau à haute résistance – le verre est un mauvais conducteur, bloquant efficacement le courant.

- Une distance de fuite étendue – les formes en disque ou ouvertes augmentent le chemin de surface pour réduire les amorçages dus à la pollution.

- Des propriétés anti-pollution – la surface lisse du verre résiste à l’accumulation de poussière, minimisant les risques de défaillance électrique.

Comment choisir le bon isolateur verre ligne haute tension : 3 considérations clés

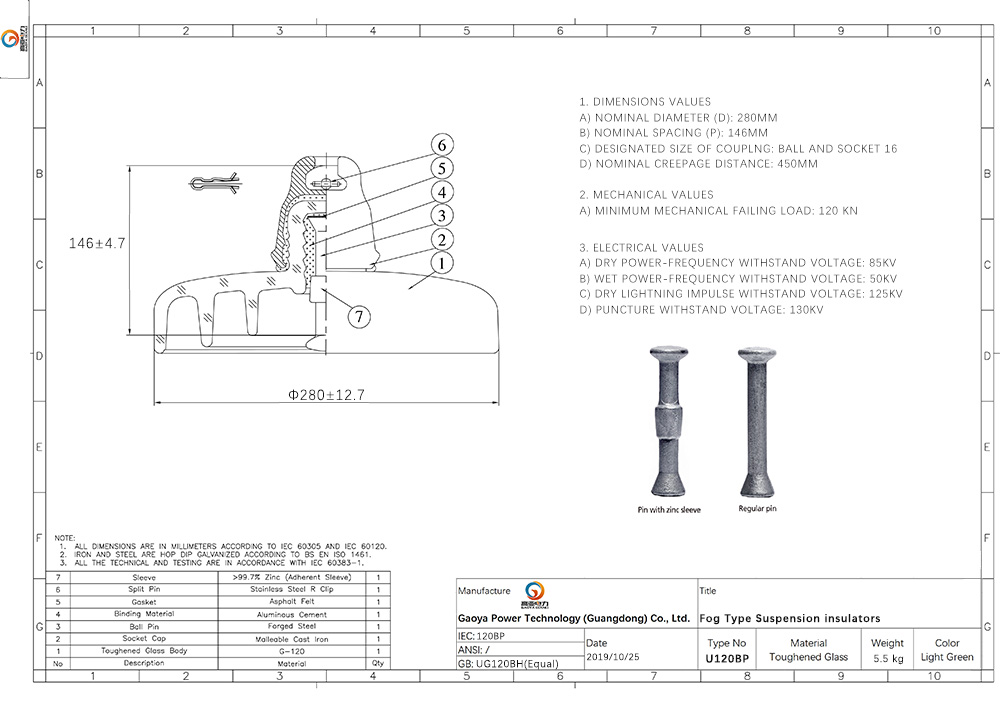

1. Plans et paramètres techniques des isolateurs verre ligne haute tension

Lors de la sélection des isolateurs verre ligne haute tension, les paramètres techniques clés suivants doivent être pris en compte :

- Distance nominale de fuite : une distance de fuite plus longue aide à prévenir les fuites ou les défaillances dues à la polarisation superficielle du matériau isolant, assurant la sécurité du matériel électrique.

- Charge mécanique minimale de rupture : par exemple 120 kN (comme montré sur le dessin).

- Taille d’accouplement adaptée : une taille standardisée facilite l’assemblage d’une chaîne stable d’isolateurs.

- Accessoires galvanisés à chaud : résistants à la corrosion pour une durabilité à long terme.

Vous pouvez choisir entre les normes internationales IEC ou ANSI selon les exigences de votre projet de transport et distribution d’électricité. Pour acheter des isolateurs verre ligne haute tension, il suffit de fournir vos plans et spécifications techniques au fabricant pour vérification. Ils produiront ensuite et vous fourniront un devis basé sur vos besoins.

2. Choix de la tension de la ligne

L’isolateur verre ligne haute tension approprié doit être choisi en fonction de la tension de la ligne. Vous pouvez vous référer au tableau ci-dessous pour vous guider.

| Types et modèles d'isolateurs verre ligne haute tension | Niveau de tension (kV) | |

| Isolateur verre profil standard | U40B(CTV175) | 10kV-66kV |

| U70BS | 10kV-330kV | |

| U70BL | 10kV-330kV | |

| U120B | 10kV-330kV | |

| U100BS | 10kV-330kV | |

| U100BL | 10kV-330kV | |

| U120B | 10kV-330kV | |

| U160BS | 10kV-500kV | |

| U160BM | 10kV-500kV | |

| U160BL | 10kV-500kV | |

| U210B | 10kV-500kV | |

| U240B | 10kV-500kV | |

| U300B | 10kV-500kV | |

| U420B | 10kV-500kV | |

| U530B | 10kV-1000kV | |

| U550B | 10kV-1000kV | |

| Isolateur verre profil anti-pollution / anti-brouillard | U70BLP | 10kV-330kV |

| U100BP | 10kV-330kV | |

| U100BLP | 10kV-330kV | |

| U120BP | 10kV-330kV | |

| U160BP | 10kV-500kV | |

| U210BP | 10kV-500kV | |

| U240BP | 10kV-500kV | |

| U300BP | 10kV-500kV | |

| Isolateur verre profil aérodynamique / ouvert | U70BSM | 10kV-330kV |

| U70BLM | 10kV-330kV | |

| U100BSM | 10kV-330kV | |

| U100BLM | 10kV-330kV | |

| U120BLM | 10kV-330kV | |

| U160BSM | 10kV-500kV | |

| U160BMM | 10kV-500kV | |

| U160BLM | 10kV-500kV | |

| U210BM | 10kV-500kV | |

| U240BM | 10kV-500kV | |

D’après l’expérience de 20 ans de Gaoya Power dans la fourniture d’isolateurs verre ligne haute tension :

- Pour les lignes de transmission 220 kV, les isolateurs avec une résistance mécanique de 160 kN ou plus sont recommandés.

- Pour les lignes à ultra haute tension (UHV) de 500 kV et plus, les isolateurs avec une résistance mécanique de 300 kN ou plus sont généralement utilisés.

3. Considérations environnementales

Différentes conditions environnementales nécessitent différents types d’isolateurs verre ligne haute tension pour une performance optimale :

- Isolateurs en verre standard : adaptés aux zones peu polluées avec des conditions environnementales conventionnelles.

- Isolateurs en verre anti-pollution : recommandés pour les zones à brouillard salin élevé, forte humidité et pollution importante, car ils possèdent une distance de fuite plus longue pour prévenir les défaillances liées à la contamination.

- Isolateurs en verre aérodynamiques : idéaux pour les environnements arides et sableux, où leur forme profilée réduit l’adhérence de la poussière et de la pluie. Ces isolateurs conviennent aussi aux zones désertiques et aux zones industrielles polluées.

- Isolateurs standard pour climats froids : dans les environnements très froids sans sources de pollution proches, les isolateurs en verre standard sont un choix approprié.

Comment les polluants affectent-ils les isolateurs verre ligne haute tension ?

Les polluants tels que la poussière, les émissions industrielles, les embruns salins et les fientes d'oiseaux peuvent affaiblir les performances des isolateurs verre ligne haute tension de plusieurs manières :

- Réduction de l'isolation et formation d'une couche conductrice

L'humidité transforme les contaminants de surface en une couche conductrice, augmentant le courant de fuite et pouvant potentiellement provoquer un arc électrique ou un contournement. - Risque de contournement par pollution

Dans des conditions humides ou brumeuses, les polluants réduisent la résistance de surface, facilitant le claquage de l'air par la haute tension et provoquant une décharge de court-circuit soudaine. - Augmentation du courant de fuite et perte d'énergie

Un chemin conducteur continu formé par les polluants humides augmente le courant de fuite, causant des pertes de puissance, une surchauffe et un vieillissement accéléré de l'isolateur.

Quatre solutions pour réduire les effets de la pollution sur les isolateurs verre ligne haute tension

- Utiliser des isolateurs anti-pollution

Conçus avec de longues distances de contournement, ces isolateurs verre ligne haute tension prolongent le chemin de surface pour le courant de fuite, réduisant le risque de contournement. - Effectuer un nettoyage régulier

Le lavage à l’eau sous haute pression ou le nettoyage manuel permet d’éliminer les contaminants accumulés et de maintenir les performances d’isolation. - Appliquer des revêtements anti-salissure

Les revêtements comme le caoutchouc silicone améliorent la répulsion de l'eau, empêchant l'absorption d'humidité et réduisant le risque de contournement. - Optimiser la configuration des isolateurs

Augmenter le nombre d'isolateurs améliore le niveau d'isolation global, réduisant l'impact de la pollution environnementale.

Pourquoi choisir les isolateurs verre ligne haute tension ?

- Résistance mécanique élevée et sécurité

Les isolateurs verre ligne haute tension sont traités thermiquement (trempés), leur conférant une excellente résistance mécanique en traction. Ils peuvent facilement résister à la tension des lignes, ce qui les rend idéaux pour les lignes de transport à grande portée et les zones venteuses. Les produits standard offrent généralement une résistance à la traction allant de 40kN à 300kN, garantissant une marge de sécurité élevée. - Surface lisse – moins d'accumulation de poussière

La surface des isolateurs verre ligne haute tension est très lisse, ce qui aide à prévenir l'accumulation de poussière. Cela leur permet de mieux performer que les isolateurs en porcelaine ou en polymère dans les zones à pollution modérée à forte, maintenant des performances d'isolation supérieures dans le temps. - Auto-rupture visible – inspection et maintenance faciles

En cas de défaut ou de claquage électrique interne, un isolateur verre ligne haute tension se brisera en petits morceaux (un processus connu sous le nom d'auto-explosion). Cependant, la ferrure métallique reste intacte et connectée. Cela permet au personnel de maintenance de repérer facilement les unités endommagées à l'œil nu, améliorant considérablement la vitesse d'inspection et l'efficacité globale. - Longue durée de vie et faibles coûts d'exploitation

Les isolateurs verre ligne haute tension offrent une résistance exceptionnelle au vieillissement et à la détérioration. Contrairement aux isolateurs en porcelaine, ils ne souffrent pas de dégradation des performances électriques au fil du temps. Avec une durée de vie typique de plus de 30 ans, ils nécessitent un entretien minimal, résultant en des coûts d'exploitation et de maintenance à long terme significativement plus bas. - Écologiques et entièrement recyclables

Le verre est un matériau non toxique et inerte qui peut être recyclé à 100% dans l'industrie verrière. De plus, les composants métalliques (tels que les calottes, les tiges et les goupilles fendues) sont recyclables, et le ciment durci peut être broyé en petits morceaux pour être utilisé comme Granulat de Béton Recyclé (GBR) dans les applications de construction.