Zinc sleeve insulators are standard insulators equipped with a zinc sleeve to enhance corrosion resistance. They are commonly used in high-voltage transmission and distribution lines, especially in ultra-high voltage applications above 500kV or in harsh environmental conditions.

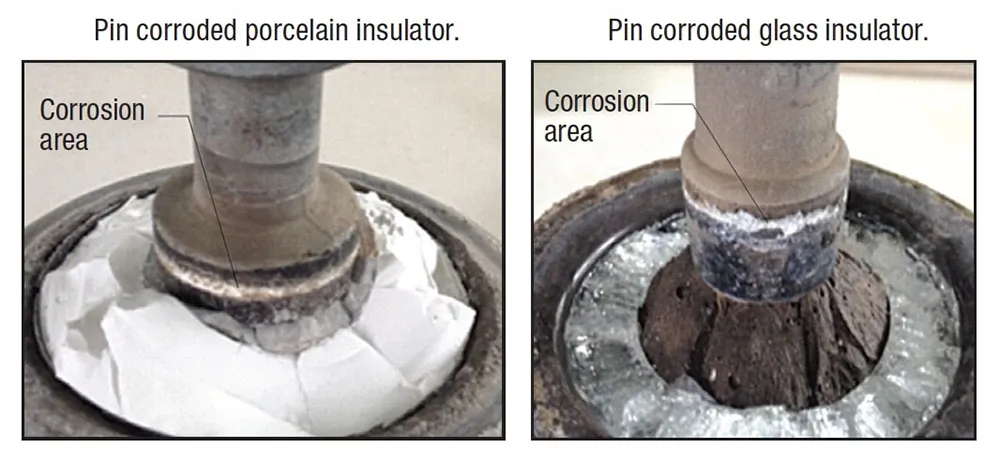

Zinc has a lower electrochemical potential than forged steel, meaning it corrodes first, thereby protecting the steel pin from rust and weakening. Even as the zinc sleeve gradually oxidizes, it does not affect the mechanical strength of the insulator. This ensures long-term performance and durability in harsh outdoor environments.

The image source: INMR.com

When Should Zinc Sleeve Insulators Be Used?

| Application Scenario | Recommendation |

| Clean or urban areas | ❌ Generally not required |

| Heavily polluted areas (coastal, industrial, desert regions) | ✅ Optional, but not mandatory |

| Extremely humid, acid rain, or salt-laden environments | ✅ Recommended for improved protection |

| High-altitude regions (prone to corona discharge) | ✅ Can be considered if needed |

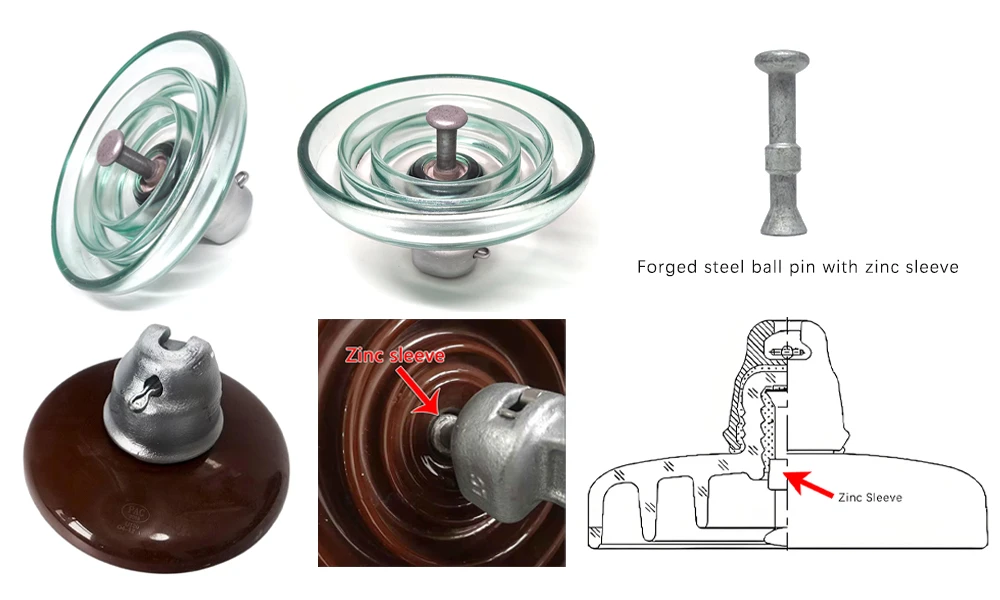

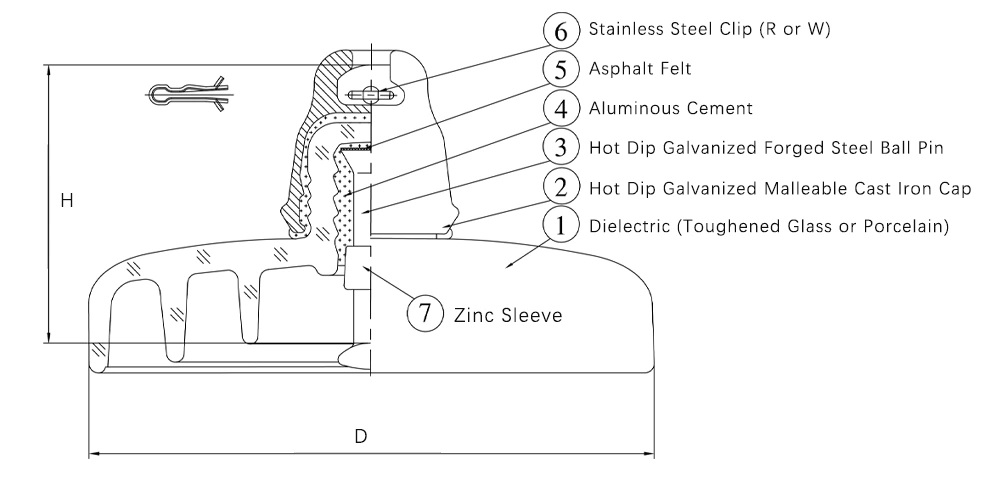

Structure of Zinc Sleeve Insulator

1. Dielectric (Toughened Glass or Porcelain)

2. Hot Dip Galvanized Malleable Cast Iron Cap

3. Hot Dip Galvanized Forged Steel Ball Pin

4. Aluminous Cement

5. Asphalt Felt

6. Stainless Steel Clip (R or W)

7. Zinc Sleeve