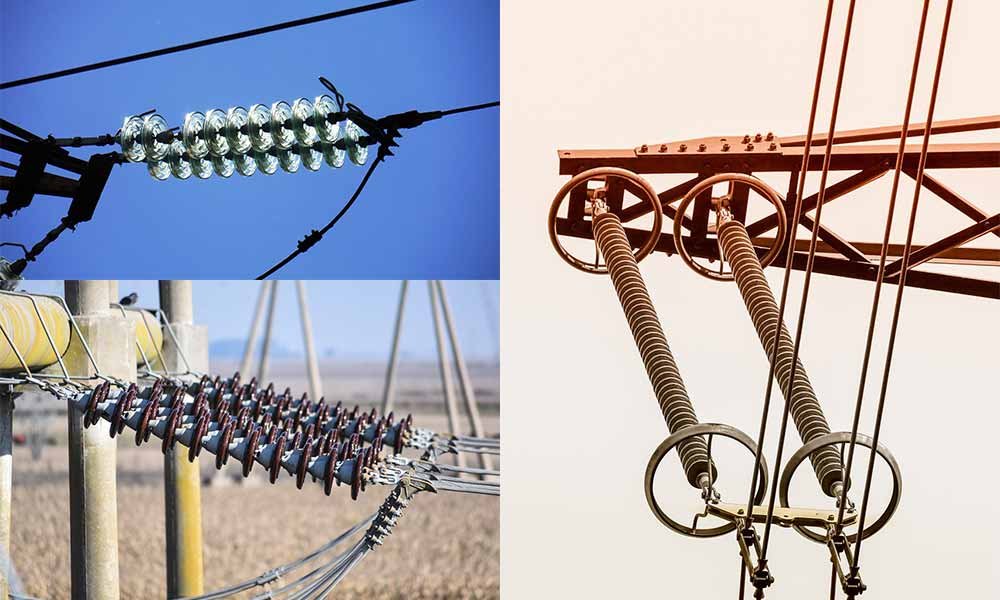

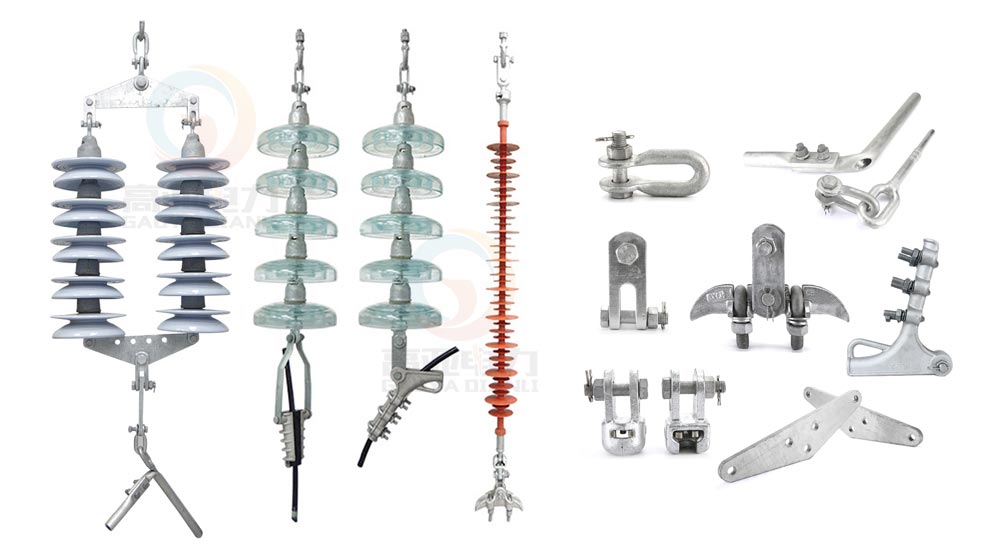

There are three types of suspension insulators: glass, porcelain, and polymer. Each offers excellent mechanical and electrical performance, with their primary difference being the materials used. For instance, polymer suspension insulators feature a silicone rubber cover and fiberglass core rod, making them lighter and easier to install.

Suspension insulators are essential components in high-voltage power transmission systems. They support conductors that carry electricity over long distances, providing the necessary insulation and stability for safe and efficient power flow. Mounted on transmission towers or poles, suspension insulators offer flexibility, ease of replacement, and secure attachment of power lines.

Why Are Suspension Insulators Preferred for High Voltage Power Transmission

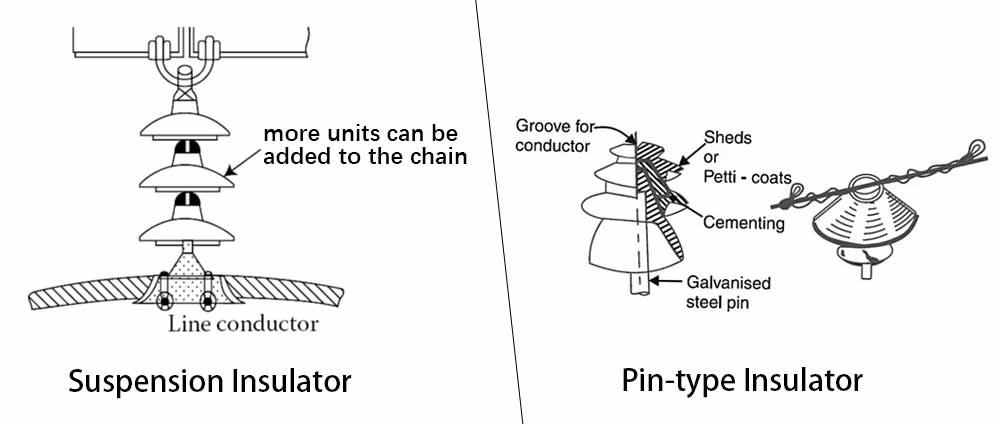

High-voltage power transmission requires components that can withstand intense electrical and mechanical stress. Suspension insulators are often preferred for their adaptability and resilience. Unlike other types of insulators, such as pin-type insulators, suspension insulators can handle much higher voltages. Their design includes a series of insulating units connected to form a chain, and each unit typically has a standard voltage rating. As a result, if a higher voltage is needed, more units can be added to the chain, enhancing flexibility.

Moreover, the flexibility of the suspension design allows them to swing under heavy wind, which protects both the insulator and the transmission line from damage. Since each unit is independent (for glass suspension insulators and porcelain suspension insulators), if one unit fails, it can be replaced without removing the entire setup. This modular approach is ideal for high-voltage transmission, where quick, cost-effective repairs are essential.

How Capacitance Works in Suspension Insulators

In suspension insulators, the concept of capacitance plays a significant role in their performance. Capacitance refers to the ability of an insulator to store an electrical charge. In the context of suspension insulators, this is important because they consist of a series of insulator discs, each with its own capacitive properties. Capacitance in suspension insulators is not uniform due to the varying distances between each disc and the transmission line conductor.

When an alternating current (AC) passes through the transmission line, each insulator disc in the suspension chain develops a potential difference (voltage). However, this potential distribution is uneven because the capacitance of discs closer to the conductor is different from those further away. This uneven capacitance distribution can be mitigated by using grading rings or other voltage distribution methods, helping ensure each disc functions effectively without being over-stressed. Proper management of capacitance is essential to extend the lifespan and efficiency of suspension insulators in high-voltage systems.

How to Draw Suspension Type Insulators

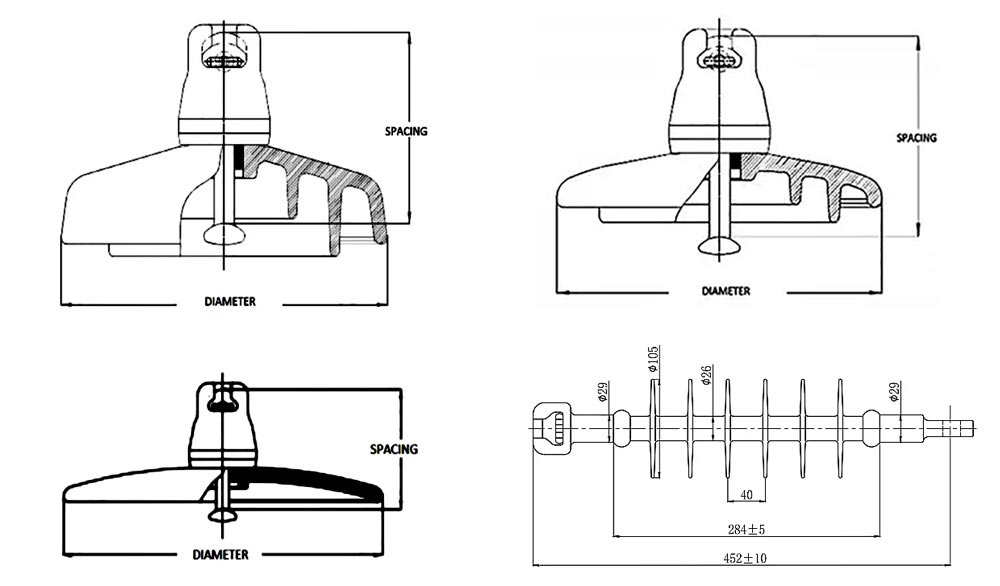

Creating an accurate drawing of a suspension-type insulator involves understanding the arrangement of its components. Start by sketching the individual insulator discs, which typically have a circular, slightly convex shape. Each disc is linked to the next by metallic fittings, creating a chain or string.

Base Disc Shape: Draw a circle or oval to represent the insulator disc.

Connection Links: Between each disc, draw a small metal link to signify the connector.

Overall Shape: Stack the discs vertically, allowing a small space between each to denote the links, showing the chain-like structure.

A completed drawing will include multiple discs in a vertical arrangement with a cap and pin system for attaching to the transmission tower at one end and the conductor at the other. This chain of discs is designed to withstand the mechanical load and environmental stress of transmission systems.

How Transmission Line Connected to Suspension Type Insulator

The connection between a suspension type insulator and a transmission line is a carefully engineered process to ensure stability and safety. Typically, the upper end of the insulator chain is attached to the transmission tower through a metallic fitting, while the bottom end is linked to the power conductor. This design keeps the conductor elevated from the tower, preventing electrical grounding and reducing potential interference with the tower structure.

The connection requires various fittings, including clamps and bolts, to securely fasten the conductor. The flexibility in the suspension design also allows the conductor to move slightly, which accommodates environmental stressors like wind or temperature fluctuations. The insulator’s chain structure helps absorb any movement or stress, protecting both the line and the tower from damage.